diy anodizing aluminum without sulfuric acid

Do not let any extra water caustic soda sodium bicarbonate or similiar near the acid bath. NO metal other than Al should be in the anodization bath at any time and you should make sure that you have a good electrical contact between the the piece and the electrode.

Hoonly China Aluminium Extrusion Profile Supplier Aluminum Extrusion Extrusion Aluminium

Aluminum wire or titanium wire to hold parts.

. Do this a bit at a time because it is an extremely exothermic reaction. What I mean is wash the acid off with distilled water then without leaving the H2O drip off quickly dunk the piece in the sulfuric acid solution and fire up the current. Mix 1 part distilled water and 1 part battery acid in the tub connect the aluminum wires to the power supply and turn on the power source for 45 minutes.

Type III Hardcoat Anodize. Anodizing works best when its done at around 70 F. When used for the anodizing process you further reduce the concentration down to.

Tanks to hold sulfuric acid anodizing bath or anodizing solution Aluminum parts to anodize. Anodizing And Dyeing Aluminum Without Battery Acid. When aluminium arrives from.

Finish is everything - anodizing does not hide a poor finish. Anodized Aluminum Anodized Aluminum Sheet Metal Siding Aluminium Sheet Anodized Your Basic Guide On How To Anodize Aluminum Parts Rapiddirect Blog Anodizing Aluminium At Home First Experiments. The ratio is 1 part acid to 3 parts water.

I will use lead wire used for. Bath in warm and bubbling. Depending on for how long the work is processed and the specific aluminum alloy being anodized this produces an anodizing thickness from about 0001 to 0008 thickness.

Of course we should never add water to acid always add the acid to the water. To anodise aluminium we need a 20 sulphuric acid solution. In Canada Sulpheric Acid is tricky to acquire without a lisence.

Remove from the dye solution and rinse with boiling water then set the dye by placing the. Dye parts if desired in warm. Putting the DIY anodizing bath on a big sheet of glass is a good idea - keeps any splashed acid off the.

Sulfuric acid high current density The suitability of common aluminium alloys to be anodised is summarised in Table 2 below. There are plenty who would just as soon leave it up to the professionals due to the highly concentrated sulfuric acid required for the. Mix 1 part distilled water and 1 part battery acid in the tub connect the aluminum wires to the power supply and turn on the power source for 45 minutesNow it is time for the desmutPour the distilled water in the container first.

It is dilute sulphuric acid at about 37. Cover your working area in something disposable. De-Smut the aluminum parts.

PRE-TREATMENT Step 1 - Cleaning Correct and adequate cleaning of the aluminium object prior to anodising is essential if the finished work is to have a uniform and attractive appearance. Aluminum oxidizes very quickly when exposed to air so the easiest way to keep it clean is to clean it just before you are ready to start working on the piece. Diy anodizing aluminum without sulfuric acid.

This results in a slightly thicker surface layer on the aluminum part. Diy Anodizing Aluminum Without Sulfuric Acid. Anodizing at a temperature over 75 degrees wont give very good results.

Degrease using mixtures of purified water and dish washing liquid with degrease formula. The great majority of aluminum anodizing is done with room temperature 20 C 68 F sulfuric acid approximately 15 by weight 10 by volume at 10-20 volts. Prepare your aluminium piece.

By using acid to strip away the existing oxide you can use exectricity to make a new layer of controlled thickness. 1Clean with purified water no distilled water available in our area 2. Diy Manual Mechanic Anodize The Aluminum Diy Coloring.

He said for more and likely better info google anodizing aluminum. But the aluminum oxide forms a shell that seals out further oxygen unlike scaly rust that allows more oxygen in. Put your container in a well ventilated area.

Should be capable of constant current have a high enough current capacity and go to at least 20 volts. Pour the distilled water in the container first. Type II Sulfuric Acid Anodize.

Type II Sulfuric acid anodize has a thickness of 00002 to 0001 inches and is better suited for dyeing parts. Degrease the aluminum parts. Anodizing and dyeing aluminum without battery acid.

Diy anodizing aluminum without sulfuric acid Friday February 25 2022 Edit. This provides a electrically conductive coating that contains a number of positive and negative ions. Anodize in the acid bath at 12 ampssquare foot for 45 minutes.

To color the part blackor whatever color make a solution of rit hair dye place the part in it and bring it to a boil this will close the pores and capture the dye. Aluminum wire or titanium wire to hold parts. Anodizing is a conversion process.

The thickness of the anodized surface depends on the length of time in the acid with the current flowing. If needed give your liquids time to acclimatize. How To Anodize Aluminum With Pictures Wikihow.

Battery acid is usually 33 sulphuric acid. Lots of stuff there on home. Type II anodizing process uses sulfuric acid instead of chromic acid.

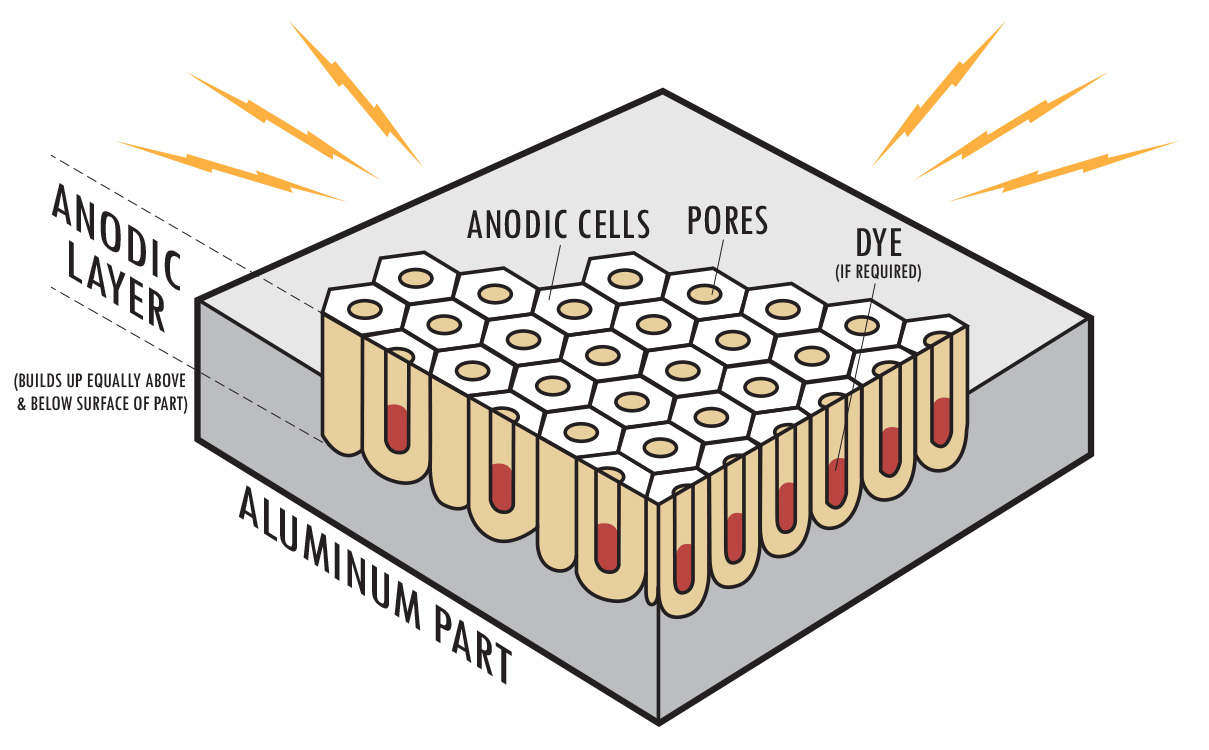

That is it converts the surface of the aluminum by eating away at it with sulfuric acid adding oxygen to the dissolved aluminum and redepositing it back onto the surface of the aluminum in the form of aluminum oxide crystals bound to the base aluminum. Clean it up with 1200 paper and maybe polish. Keep temp at 70-72 degrees F.

Ad Our Plug N Plate Kits Are as Easy as That. Therefore to every 1 litre of battery acid we need to add 650ml of de-ionised water. Sulfuric acid battery acid to make acid bath.

Clean the aluminum parts. To anodise aluminium we need a 20 sulphuric acid solution. Then remove your aluminum from the tub and rinse it with distilled water.

Then add the sulfuric acid. The great things about anodizing is that the surface now has a coating of aluminum oxide - the. This shell of transparent aluminum oxide is thin but tough- the crystaline form of aluminum oxide is sapphire.

Battery acid is not concentrated sulphuric acid. Are there alternatives that can be used to anodize aluminum. Put your container in a well ventilated area.

Heat to boiling and allow the metal to boil in the solution for about 30 minutes. Remove parts from acid bath and rinse with distilled water. Add color to your anodized metal by placing the metal into the dye solution.

I am working on aluminum front panels for diy music equipment and the surface is way too easy to scratch even on 6160 gauge aluminum.

Measuring Anodizing Thickness On Aluminum Resources Defelsko

Anodizing Aluminum Anodized Aluminum Sodium Bisulfate

Home Aluminium Anodising Process Part 1 Youtube

How To Anodize Aluminum Without Strong Acid Make

How To Anodize Aluminum Diy Corrosion Prevention Methods Youtube

Diy Manual Mechanic Anodize The Aluminum Diy Coloring

How To Anodize Aluminum The Federal Group Usa

Everything You Need To Know About Anodizing Aluminum 3erp

Your Basic Guide On How To Anodize Aluminum Parts Rapiddirect Blog

Homemade Anodizing Automatic Artisan

How To Anodize Aluminum 4 Simple Dye Techniques Youtube

Diy Anodize Aluminum At Home With A Battery Charger Youtube